OUR AIM – NO ACCIDENTS

PLASTIC MOULDS DEFINE PLASTIC PARTS QUALITY

We provide quality-focused solutions in moulds and dies, siren alarms, gas storage, and industrial components in plastic and aluminium.

Siren Alarm

Moulds & Dies

Industrial Parts

Gas Storage Solutions

Plastic Moulds for Industries

At DSW Industry, we specialise in designing and manufacturing high-quality plastic injection moulds, tailored to meet the precise needs of diverse industries.

Discover how our plastic moulds ensure quality and efficiency in manufacturing.

Follow Best Practices for Plastic Molds — Save Costs

The Industries We Serve

DSW employs a versatile plastic moulding process to serve diverse industries, producing complex, high-precision plastic components. Applications of our plastic moulds and moulding solutions span across:

- ConstructionExpert & modern systems

- EnvironmentalWaste management

- MachineryEquipment relocation

- Electrical ServiceElectrical supply stores

- PredictiveAsset optimization

- Weld, FabricationMachine shop work

- EngineeringCognizant technology

- HVAC TechniciansHave largest Network

Jack Cage – Engineer

Dare to Be Aware

Because no plant can afford an inefficient operation or unplanned downtime, Marshall Industrial Technologies’ Mechanical Services Group focuses on keeping your operation running at peak performance.

Have another day – By being safe today!

A Good Quality Is Not Accidental

Burglar Alarms

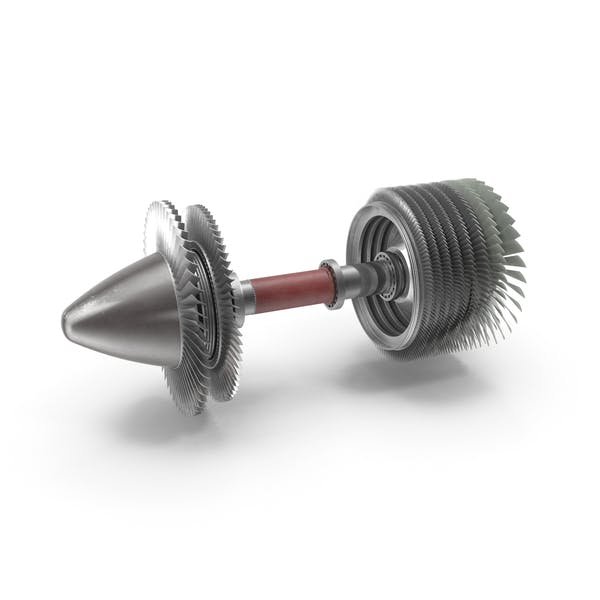

Mould Toolings

Precision moulds and die casting tools for plastic and metal parts.

Gas Storage & Supply

Gas cylinders, dewars, or cryogenic tanks for reliable storage and delivery.

Get A Free Quote For Your Project

Feel free to contact us and get a free quote

There are several types of plastic moulds, including:

- Single-cavity moulds: Produce one part at a time.

- Multi-cavity moulds: Produce multiple parts simultaneously in the same mould.

- Hot runner moulds: Use a heated channel to inject plastic, reducing waste and increasing efficiency.

- Cold runner moulds: Have unheated channels and can lead to more waste but are simpler to design.

A plastic injection mold is a custom-made tool used in the injection molding process to shape molten plastic into a specific part or product. The mold typically consists of two halves: the cavity and the core, which form the desired shape of the plastic part.

In the injection molding process, molten plastic is injected into the mold cavity under high pressure. The mold is then cooled, solidifying the plastic into the desired shape. Once cooled, the mold opens, and the finished part is ejected.

Plastic injection moulds are used across a wide range of industries, including:

- Automotive (e.g., dashboard components, interior parts)

- Electronics (e.g., phone casings, connectors)

- Medical (e.g., syringes, surgical instruments)

- Consumer goods (e.g., containers, packaging)

Check out our news and updates

Latest News and Updates

I just made a public announcement here at the office that if there was such a award for Vendor of the Year, you would receive it. We would all vote for you. Very demanding HUGE customer, and you have just went above and beyond!

John DoeBusinessman

I wanted to thank you and your crew for getting this turned so quickly! Much appreciated and this is why I always choose XTRA for my needs! Well done and this service level is EXACTLY why I choose to use XTRA on my motor!

John DoeBusinessman

XTRA always has what we need at the right price. Tom is a great help even when it’s something that is hard to find. From the office to Tom or anyone else in back, its always a pleasure to order things that you know will be right the time