What is Mould Polishing and Why Does it Matter?

When it comes to plastic injection moulding, surface quality is everything. A well-polished mould doesn’t just look impressive – it directly impacts the finish of the parts produced, their ease of release, and even the overall efficiency of the moulding process.

In this article, we’ll explore what mould polishing is, why it’s important, the tools and materials used, and the key steps to achieving a flawless finish.

What is Mould Polishing?

Mould polishing is the process of refining the surface of a mould cavity using tools such as:

- Abrasive paper

- Oilstones

- Felt wheels

- Polishing compounds

The goal is to create a smooth, mirror-like finish.

Why polish a mould?

- Better product finish – ensures parts are smooth, glossy, and visually appealing.

- Easier part release – prevents sticking and reduces ejection issues during moulding.

Tools and Materials

- Abrasive paper: Available in a wide range of grits, typically 150#, 180#, 320#, 400#, 600#, 800#, 1000#, 1200#, 1500#, and beyond. The higher the number, the finer the grit, with each grade serving a different polishing stage.

- Oilstones: Standard grades include 120#, 220#, 400#, and 600#, mainly used for initial polishing to remove machining marks.

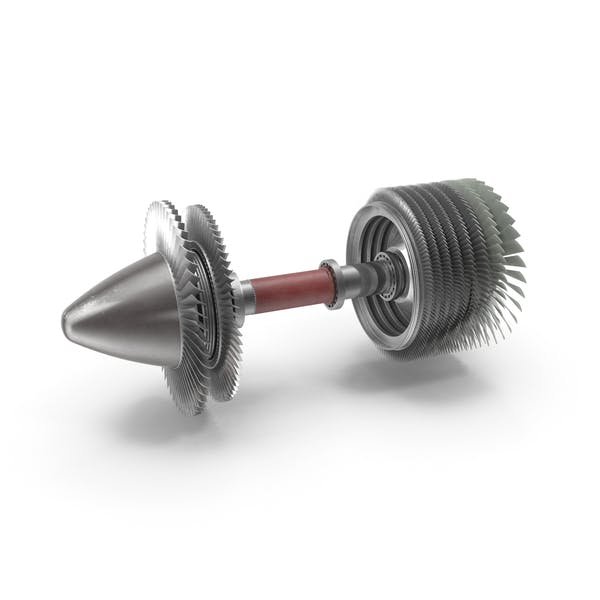

- Felt wheels: Manufactured in cylindrical, conical, or square-ended shapes. Used with polishing compounds for final finishing.

- Polishing compounds: Supplied in different grades such as #1 (white), #3 (yellow), #6 (orange), #9 (green), and so on, allowing for fine finishing and achieving a highly reflective surface.

- Other tools: Alloy files, diamond points, bamboo sticks, fibre stones, and rotary polishing machines. Bamboo strips are useful for holding abrasive paper against surfaces, while rotary grinders speed up the process.

The Polishing Process

Mould polishing is usually done in three main stages:

- Rough Polishing

- Removes machining marks and EDM (electrical discharge machining) layers.

- Uses oilstones in sequence (#180 → #1000).

- Requires consistent 70° cross-grinding motion for even results.

- Semi-Fine Polishing

- Uses abrasive paper with kerosene.

- Focus on removing surface irregularities (round edges, orange peel).

- Paper should only be used for 10–15 strokes per side to maintain cutting ability.

- Fine Polishing

- Achieved with diamond pastes and felt wheels.

- Typical sequence: 9μm → 6μm → 3μm → 1μm → 1/2μm → 1/4μm.

- Produces a mirror-like, high-gloss finish.

Working Environment

Polishing results depend heavily on the environment:

- After 1200# abrasive paper, polishing should continue in a dust-free room.

- For 1μm precision or better, work must be done in a clean polishing chamber.

- For ultra-precision polishing, even the smallest dust particle or flake of skin can ruin the finish.

Best Practices & Tips

- Use softwood or bamboo sticks for curved surfaces; harder wood for flat surfaces.

- Change polishing direction by 45°–90° between grit changes to spot remaining scratches.

- Clean the surface thoroughly before moving to finer abrasives.

- Avoid over-polishing – it can cause defects like orange peel or pitting.

- Prevent heat build-up by avoiding high-speed polishing wheels.

Factors That Affect Polishing Quality

Several factors determine the success of mould polishing:

- Operator skill – Since most polishing is manual, technique is critical.

- Surface condition – Machining marks, EDM layers, or heat stress can make polishing more difficult.

- Steel quality – High-grade steel produces the best results, while impurities cause issues.

- Heat treatment – Poor hardening can lead to uneven hardness, complicating the process.

No comment