What is Design for Manufacturability (DFM)?

Design for Manufacturability (DFM) is a design approach that ensures products are easy to manufacture, cost-effective, and meet quality standards. By considering the production process during the design phase, engineers can avoid costly issues, reduce errors, and speed up time-to-market.

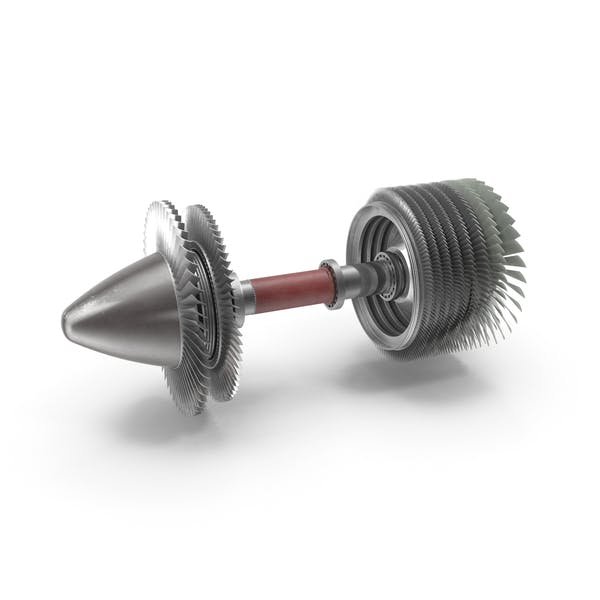

DFM covers factors such as product dimensions, materials, assembly, and production methods. Common tools include CNC machining, rapid injection moulding, vacuum remoulding, and 3D printing to validate designs before mass production.

DFM is a proactive approach that incorporates the needs of manufacturing teams and supply chain partners from the start of a project, rather than trying to fix problems late in the development cycle.

In mouldmaking, DFM is particularly critical. A mould’s design directly impacts production efficiency, part quality, and tooling costs. Applying DFM principles during the mould design phase enables manufacturers to optimise material usage, minimise defects, and accelerate production timelines.

Core Principles of DFM

- Simplification

Reduce the number and complexity of parts in a mould design. Fewer components mean lower material consumption, less labour, and a reduced risk of assembly errors. - Standardisation

Use standard, off-the-shelf components wherever possible rather than custom parts. This approach lowers costs, simplifies sourcing, and reduces inventory needs. - Material Selection

Choose materials considering cost, availability, durability, and compatibility with the moulding process. The right material ensures smoother production and long-term mould reliability. - Simulation and Analysis

Simulation software predicts the flow of molten material, identifying potential imbalances. This enables adjustments to be made before the actual plastic moulding process begins. - Tolerance Specification

Set the loosest tolerances that still meet functional requirements. Overly tight tolerances increase manufacturing complexity, time, and cost. - Minimise Secondary Operations

Design moulds and components to require minimal post-production steps, such as polishing, painting, or additional machining. - Ease of Assembly (DFA)

Pairing DFM with Design for Assembly ensures components are easy to fit together. This reduces labour time, error rates, and the need for specialised tools.

Key Considerations in DFM for Plastic Mould Making

- Part Geometry

- Simplicity is key: Complex part geometries can increase production time and cost. A design that avoids undercuts or requires minimal features will reduce the complexity of the mould.

- Draft angles: Parts should have adequate draft angles (typically 1–3°) to ease ejection from the mould. Insufficient draft angles lead to more wear and difficulty in part removal.

- Wall Thickness

- Uniform thickness: Parts should have a consistent wall thickness to avoid defects like warping, sink marks, and internal stresses. Gradual transitions between different thicknesses are preferable to sudden changes, which can cause uneven cooling.

- Ribs and gussets: For reinforcement, designers should use ribs instead of thick walls to avoid material wastage and ensure uniform cooling.

- Material Selection

- Choosing the right material for injection moulding is crucial for functionality, cost, and manufacturing ease. The material must be compatible with the mould and the injection process.

- Thermoplastics are often preferred for injection moulding, but their properties (e.g., flowability, shrinkage) need to be taken into account in the design.

- Mould Design

- Mould Flow Analysis: This step helps predict how the molten plastic will fill the mould and identify potential issues such as air traps, weld lines, or cold spots.

- Mould Cooling: Efficient cooling channels must be incorporated into the mould to ensure uniform cooling of the plastic part, which helps reduce cycle times and prevent defects.

- Ejection Systems: Proper design of ejection pins or air vents is crucial to avoid part damage during removal from the mould.

- Tolerances and Fit

- Tighter tolerances can increase the cost and time required for mould making. DFM encourages the use of reasonable tolerances that balance product quality and cost-efficiency.

- Tooling and Process Optimization

- The mould tool design must be optimized to minimize wear and tear during production. This involves careful selection of materials for the tool and the design of cooling and venting systems to maintain the tool’s lifespan.

- Automation: Where possible, automated processes like robotic part removal and in-line inspection can further reduce costs and improve accuracy.

- Production Volume Considerations

- For low-volume production, simpler mould designs may be more cost-effective, while high-volume runs may justify the use of more complex, durable moulds. DFM takes this into account to avoid over-engineering the mould for small production runs.

DFM Tools in Plastic Mould Making:

- CAE (Computer-Aided Engineering) Tools: Software like Moldflow or SolidWorks is widely used for simulating and analysing injection moulding processes. These tools help predict and resolve issues before mould production starts.

- DFM Software: Some tools offer integrated Design for Manufacturability checks that automatically flag design issues that could complicate the manufacturing process.

Benefits of DFM in Mouldmaking

- Reduced Costs: Streamlined designs reduce material waste, labour, and tooling expenses.

- Faster Time-to-Market: Early identification of manufacturing challenges prevents delays and redesigns.

- Improved Quality and Reliability: Fewer defects and errors lead to higher-quality parts and consistent performance.

- Enhanced Production Efficiency: Simplified moulds enable smoother, more predictable manufacturing processes.

- Easier Scalability: Designs optimised for manufacturability are simpler to produce in large volumes without complications.

Conclusion

Incorporating Design for Manufacturability (DFM) in mouldmaking is essential for creating cost-effective, high-quality, and scalable products. By considering production capabilities, material choices, tolerances, and assembly requirements early in the design phase, manufacturers can reduce costs, improve efficiency, and ensure consistent product quality. DFM is not just a design strategy—it’s a proactive approach that strengthens the entire production process.

No comment